Rwandan Coffee Companies Embrace Circular Practices Through Peer Learning Visit

“It was an invaluable learning experience. On behalf of our company, I plan to expand the vermicomposting system not only at the washing station but also at three farm sites. Additionally, we will enhance our wastewater lab analysis during the season, based on insights from the visit,” Wellars Karangwa, General Manager at Muhondo Coffee Company, describes his experience.

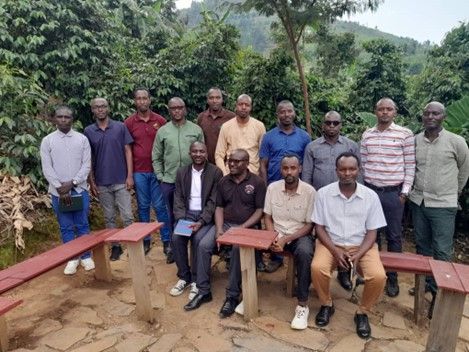

In February, nine coffee companies from across Rwanda participated in a hands-on learning visit to the coffee washing station of Gitesi Coffee Company in Karongi District.

The study visit provided participants with an up-close look at sustainable practices in wastewater management and coffee waste valorization, demonstrating how circular solutions can enhance environmental performance and operational efficiency in the coffee sector.

The visit was organized by the International Trade Centre (ITC) under the EU-EAC MARKUP II programme, as part of the Resource Efficiency and Circular Production (RECP) coaching component.

Turning Coffee Waste into Value

Coffee processing in Rwanda generates large quantities of wastewater and coffee pulp, by-products that, if unmanaged, can pollute the environment and degrade soil quality. Coffee pulp alone accounts for 41% of the coffee cherry and is often discarded or poorly composted. Similarly, wastewater from washing stations is rarely treated, posing a threat to nearby water sources.

However, Gitesi Coffee Company has taken a different approach. Through the adoption of circular practices, the station has developed a closed-loop system that transforms waste into valuable resources. Its advanced wastewater treatment system ensures that water is free of contaminants before being safely discharged into the environment. Additionally, its innovative vermicomposting process turns coffee pulp into high-quality organic fertilizer, improving soil health for coffee crops and beyond.

From Demonstration to Replication

For many participants, this was their first opportunity to witness such practices in action.

“Seeing the quality of compost that Gitesi produces, I realize my own composting efforts have been ineffective due to limited knowledge,” said Benic Bisangabagabo, Manager at Hobe Coffee.

Peer Learning in Action

The visit served as a catalyst for practical learning, open dialogue, and actionable insights. By engaging directly with Gitesi’s team and operations, participants gained the knowledge and confidence to upgrade their own systems. Many expressed concrete plans to improve composting techniques and implement proper wastewater treatment.

As a model for circular production, Gitesi Coffee Company demonstrated that sustainability and efficiency can go hand in hand, offering inspiration and guidance for Rwanda’s growing coffee sector.